1. Our frames Are 100% interchangeable with OEMs, and adopt significantly re-enforced material and D

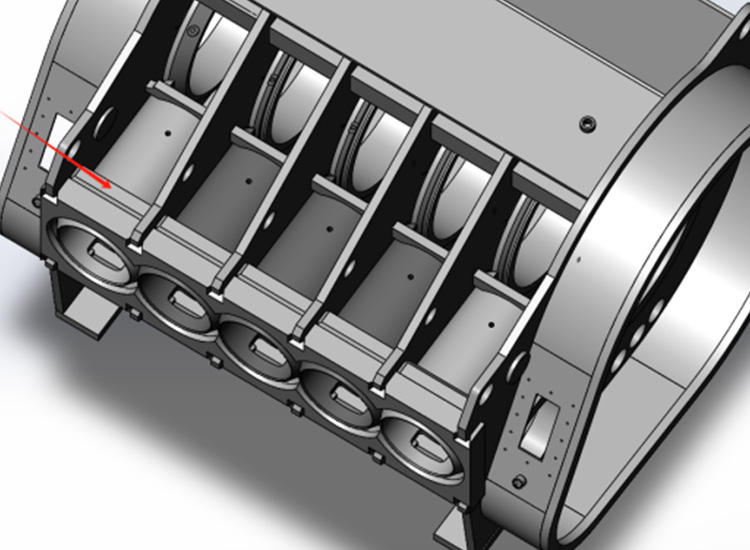

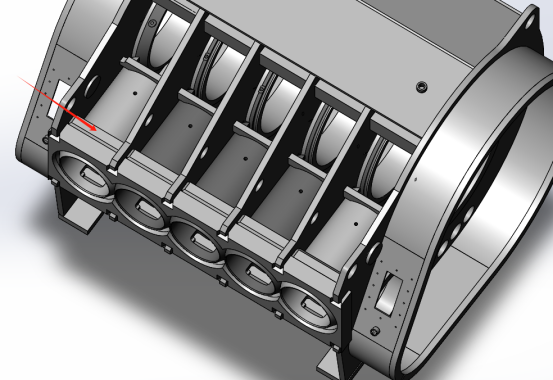

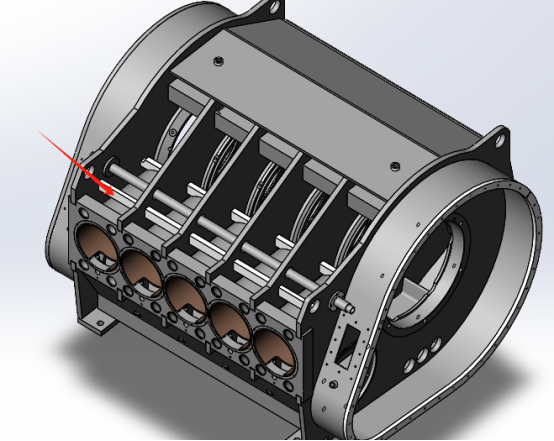

1. Our frames Are 100% interchangeable with OEMs, and adopt significantly re-enforced material and Design.

2. The reinforcing plate is to be relocated to the panel, with inclined slopes and panel welding to the upright panel. This significantly reinforces the strength of the panel without altering its structure. Previously, this area experienced cracks between the panel and upright due to insufficient welding strength, particularly due to the high forces endured at this connection point with the hydraulic end. This enhancement extends the overall lifespan by 20%.

The original design placed this reinforcement plate between the hydraulic tube and the panel.

3.Welding:

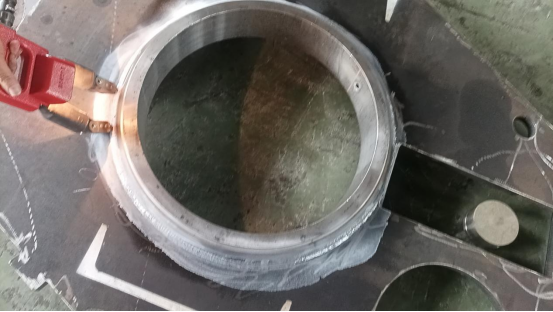

1:Conduct a non-destructive testing (NDT) inspection immediately after welding the bearing seat and the upright panel to promptly identify any issues. Since it's not feasible to perform a comprehensive inspection on this area once the welding is completed and the product is finished.

2:Perform another NDT inspection before conducting heat treatment after welding.

3:Conduct an additional NDT inspection after heat treatment.

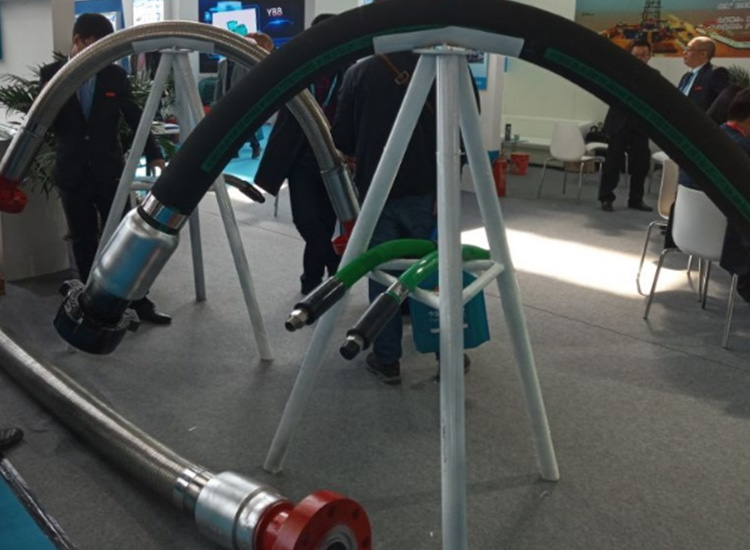

This is the inspection photo before the heat treatment

Photo of welding after heat treatment

2. Quality Control: During our manufacturing process, we conduct initial inspections, in-process inspections, and final inspections;

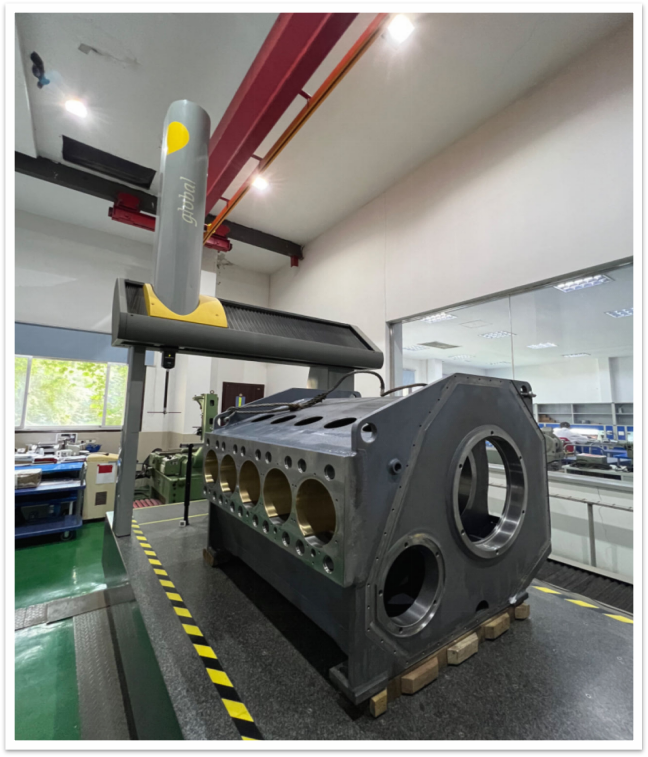

3. Three-coordinate measurements of critical dimensions inspection on every single Frame to guarantee the precision of each frame.